Partner with STMicroelectronics

Martinsson Elektronik is partnered with STMicroelectronics delivering Tailor-made display solutions & HMI systems based on STM32 microcontrollers and microprocessors.

A modern display solution is developed from a market perspective and plays a crucial role in how the whole product is perceived by the user. A good display implementation elevates the product, while a poor one lowers it.

In most cases, the display is the part of the product that the user focuses on, reads and interacts with. How it works together with the application therefore becomes important, as the expectation is that it will function largely in the same way, whether it is in a smart phone, in a car or in an industrial product. The graphical interface in the product will be decisive for the user experience, the impression the product makes and how the brand is perceived.

Today’s technologies enable increased flexibility in creating display solutions based on user needs, function and design. Therefore, the display becomes an important design element to take into account early in the project when designing the entire product.

Before developing product ideas, it is assumed that you have a deep understanding of the company’s DNA, which unites the company’s and the product’s core values. Through user studies, you gain deeper insight into how the product is used. The product format is the product’s identity – that is, the brand’s expression in the product – and what makes it unique in comparison to competitors.

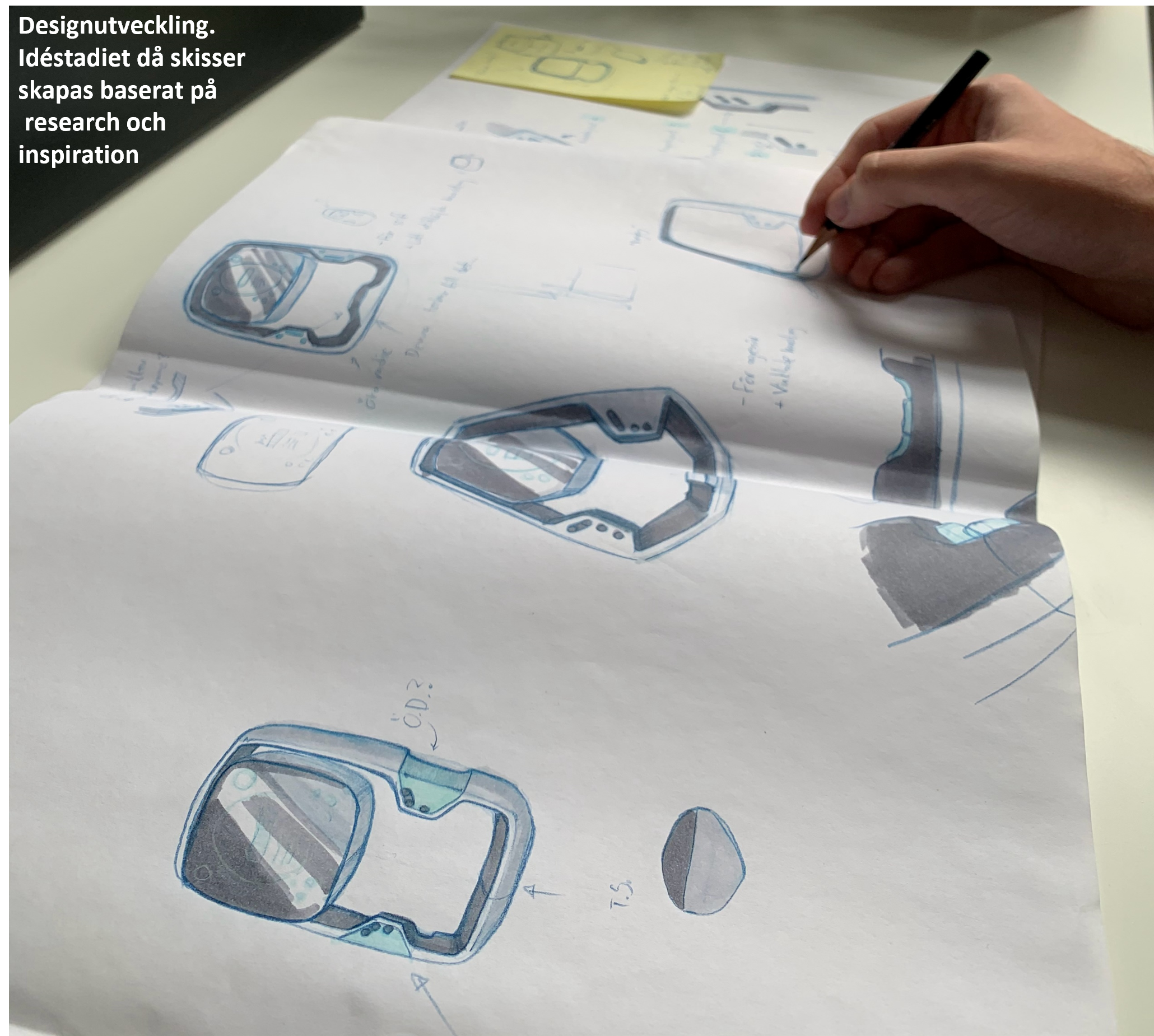

In the idea stage, the product’s development possibilities are explored both in terms of expression and functionality, but also in terms of manufacturing. Here, in other words, an idea bank is created which is the basis for the subsequent concept phase. In concrete terms, this is a sketch phase where, based on research & inspiration, you work with function, form and structure and highlight ideas about materials and manufacturing possibilities.

Aspects to consider could be, which laws and directives does the display need to handle? What will the electrical architecture of the system be in terms of cabling, EMC and manufacturability? What is most important – price, availability, quality, adaptability and/or time-to-market?

The development of display technologies is primarily driven by the consumer market in the form of smartphones, tablets, personal computers and TVs. Manufacturing is symbolized by high volumes but with a relatively short lifespan. The industrial market takes longer to adopt new technologies because that market has completely different requirements in the form of longer product life cycles, extended temperature ranges and spare parts storage over a long period of time. The technology transition is happening more slowly, but we can gradually see the same display technologies in industrial applications as in consumer products.

Which display technology to choose is of course dependent on what was arrived at in the design phase and what is to be shown on the display, how it is intended to be used, what environment it will operate in, how long it is intended that it can be produced as well as how it should be integrated with the product electrically and mechanically. Today’s technologies create good conditions for meeting all needs. The most common technologies for new products today are colour displays, TFT LCD and OLED.

An OLED display does not require an additional light source. The technology is based on carbon-based material and when power is applied, it becomes luminescent. The advantage is that the display is lighter and thinner than conventional TFT screens, the contrast is higher because only the leading pixels are lit and the viewing angles are very good. OLED is mostly used in consumer electronics. The disadvantages are short life and limited flexibility.

TFT LCD is a well-used and long-established technology. There is currently no new technology that completely replaces TFT LCD. It is a relatively inexpensive technology with a large variety of solutions depending on the needs of the application. Unlike OLED, the background lighting is based on a separate light source, the so-called LED backlight. The color reproduction and contrast are very good and it is possible to get displays in all sizes. Today’s TFT displays have, thanks to IPS (In-plane switching) technology, better colour reproduction and very good viewing angles.

Touch sensors (touch), here there are also choices to be made, but it is the touchscreen technology (Projective Capacitive Touch) that most people choose, although the choice depends on how the user is supposed to interact with the display and what environment it is to be used.

PCT (Projective Capacitive Touch) is a capacitive touch screen panel consisting of an insulator – glass – coated with a transparent conductor, indium tin oxide (ITO). The human body is also an electrical conductor so when a touch of the screen’s surface occurs it results in a distortion of the screen’s electrostatic field, measurable as a change in capacitance and thus the touch registers a pressure.

It is with PCT that the great design possibilities open up. There are a number of different possibilities to create a display that aligns with the design strategy and product design. Here you can use the top layer of the display, which can consist of Plexiglas or glass. You can choose to have an enlarged glass that extends over the active touch surface. This means that you can shape the glass as you wish in terms of size, thickness, shape, color and perforation. We can have screen printing such as logo or product name. You can also choose different types of coating to e.g. prevent reflections or fingerprints on the glass. Also antibacterial protection or strengthened vandal protection. You can optically glue the intermediate layers in the display to reduce reflections and at the same time increase color reproduction and contrast. PCT is by far the most chosen technology in new products for indoor and outdoor applications.

With impressions from the concept work, a concept is drawn up that meets the product requirements. We work with function concepts and form concepts respectively, where the function concept describes basic structure and function while the form concept describes the basic design idiom that is intended to be used. These concepts are used as a basis for the subsequent design definition phase.

The expression of the product is largely in the details and therefore it is in the definition phase that the expression of the product is developed in detail and defined. The substrates are developed to define colour, surface structures and product graphics.

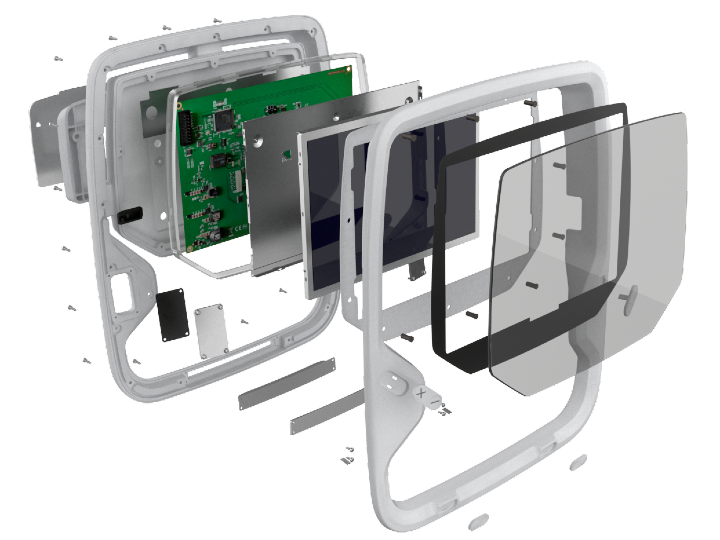

With the CAD model, photorealistic images of the product are visualized (renderings). The result forms a qualitative basis for subsequent design definitions. Renderings can be advantageously used for marketing purposes. After that, product development starts.

More and more customers choose to buy a function instead of components, i.e. ready-made modular products (building elements) instead of the individual components.

The car industry changed a long time ago and today consists of assembly lines where both development and supply have been handed over to suppliers of functions and building elements such as headlights, dashboards and other things. The advantage of this is that the company can rationalize costs by focusing on the key competencies in its operations.

The choice of partners will naturally be suppliers who are specialists in their product area and usually from a category that delivers to other customers with similar needs and many times also to competitors. In this way, you can reach both specialized development knowledge and products at competitive prices. This is now reflected in other industries. A supplier is not shared with competitors, but rather with other companies with widely different operations but with similar needs, which means that conflicts of interest rarely or never arise.

The advantages of buying a function instead of components are many, but are largely controlled by which key competencies the customer sees as strategic in their own business. By purchasing a modular product, the supplier takes over the product maintenance, and then has to handle “end of life”, design changes, documentation, test systems, aftermarket and more. Quality can be ensured because the supplier assembles the module and tests the function. The material supply also becomes more efficient as only one article needs to be handled. Above all, what drives the development of modular products (building elements) are “total cost of ownership” calculations, which are becoming increasingly common in connection with the development and purchasing process.

With over 20 years of experience in display integration, we can help you create a best-in-class product

”With the help of Martinsson's expertise in displays and electronics, we have together designed a new world-class digital X-ray system. The result is increased competitiveness.”

Connect with our Business Development Manager Daniel Aspeskär and we will see to your needs.